Lean is the way to go in Pigs, and not just on the Plate

Posted in Uncategorized on 20/04/2018.

When you hear “Lean” and “Pigs” in the same sentence, it is natural to automatically think of the best cuts of pork. But in this case, it’s not about taking the fat out of streaky bacon, it’s applying the toolset and principles of Lean Manufacturing in an area where it hasn’t previously had much exposure in Ireland; the Pig Farming Industry.

That’s what Leading Edge Group, amongst other companies, has been doing for the past couple of months. As part of a Bord Bia/ Teagasc/ Enterprise Ireland initiative, 30 of Irelands top pig farmers have been participating in a large scale feasibility study looking at the improvement’s that can be made to a farms operations and profitability by applying the well-established Lean Manufacturing tools and principles on Piggeries. As part of the project, consultant Barry O’Brien has worked closely with several clients, one of whom is Pat O’Keeffe of O’Keeffe Piggeries based in Ballylough, Mitchelstown, Cork, Ireland.

Pat has had previous exposure to Lean, having served for many years on the board of Dairygold Co-op, and he had seen the results of Lean having been implemented, but he hadn’t experienced the implementation process first-hand. As part of the stakeholder group on Pig farming in Teagasc, he jumped at the opportunity to participate in the Lean project. “It’s great to see the impact of the Lean project on my farm” said Pat. “You can see the lads enjoying the training, and more importantly, they are seeing and reaping the benefits of the project and responding to the changes being proposed and implemented”.

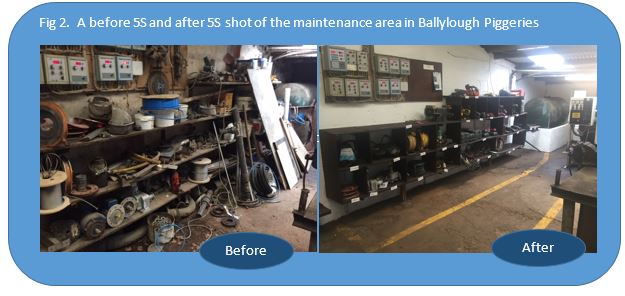

A large part of the Lean initiative on Pat’s farm has been to generate a farm-wide 5S plan, targeting specific problem areas for the initial implementation. “By performing the 5S on an area, it peels back the excess in the area, and it exposes the waste. By doing this, the actual problems in the area are easier to identify and then tackle” said Pat. “Before this, we had no system and we were targeting what we thought was wrong, rather than what we knew was wrong”. Removing clutter has aided in identifying specific issues (what is wrong?) and then finding their root cause (why?). This will aid in further savings on the farm including easier adherence to standards, reduction of feed wastage, reduction in wasted labour looking for tools, implements, etc. “Pig Farming is a 24-7 business and if there is a mechanical problem at 3am in the morning and I need to find specific tools, it makes it much easier when we have the system in place to ensure that all implements have been recently tested to ensure that they are working and that they are always put back into their place”.

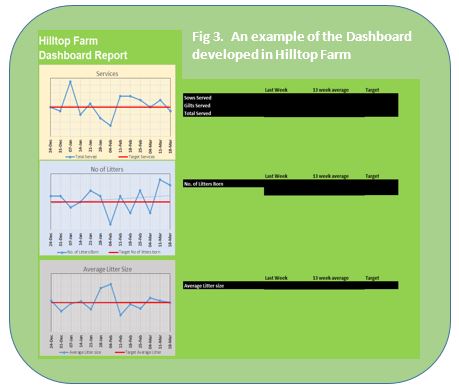

Another farmer participating on the program is Eugene Sheehan of Hilltop farm, also in Mitchelstown. “It’s impossible to be perfect and you can always be improving” states Eugene. Part of the work performed on Eugene’s farm practice has been to use the existing data to generate Dashboard reports, visualising the key trends in the Piggeries performance over time, and not just the previous weeks snapshot. Eugene believes “It’s important not to be too complacent and I’m always on the lookout to try new things and keep on top of the most recent improvements in Pig Farming technology. Having this data present allows me more time to make the strategic decisions”

A third farm participating in the Lean project is O’Brien farms, a group of pig farms, headquartered in Carrigtwohill, Co. Cork. Having had no experience of Lean Manufacturing, Jimmy O’Brien was eager to participate in the project. “While we are confident in the pig farming sector that we are performing well globally, we don’t learn enough from other Industries about how they structure themselves, and about how they solve problems” Jimmy recounted. Part of the project run on O’Brien Farms was a training day where 9 key members of staff, including all of the pig farm leaders, got together and had a very successful interactive training on Lean, with a focus on workplace organisation, visual management and problem solving techniques. Part of O’Brien farms strategy ongoing will be to ensure that this group meet more regularly to learn from each other. Rolling out 5S onto each farm will be part of the forum for this, and some healthy competition is expected between farms.

All three business leaders agree that people are their most important resource. In addition to 5S, the data driven waste reduction principles of Lean have aided all in several strategic decisions, from feed wastage reduction, accounting practises, capital expansion decisions, stocking densities, sales decisions, ongoing strategies etc. and the principles imparted during the Lean project will continue to help make these decisions in the future. Pat O’Keeffe is clear in his thinking about the future plans of the business and views Lean Manufacturing as a key part into sustaining his business ongoing. “Lean is the way to go in Pigs, and not just on the plate” he says, smiling.

Barry O’Brien – Senior Consultant

Keep up to date with the latest news by following us on LinkedIn, Facebook and Twitter.